Compounding machinery for Rigid PVC

During the first half of the nineteenth century the creation of PVC from vinyl chloride (VC) was first described. Large-scale PVC production started in 1928 in the USA and 1930 in Germany. By the time the Second World War ended, it was already the most-produced plastic. With a chlorine content of 56.7% molar mass, PVC is a welcome co-product in chlorine chemistry. Due to their low content of hydrocarbon-based components, PVC materials have a comparatively favourable energy balance and CO2 footprint.

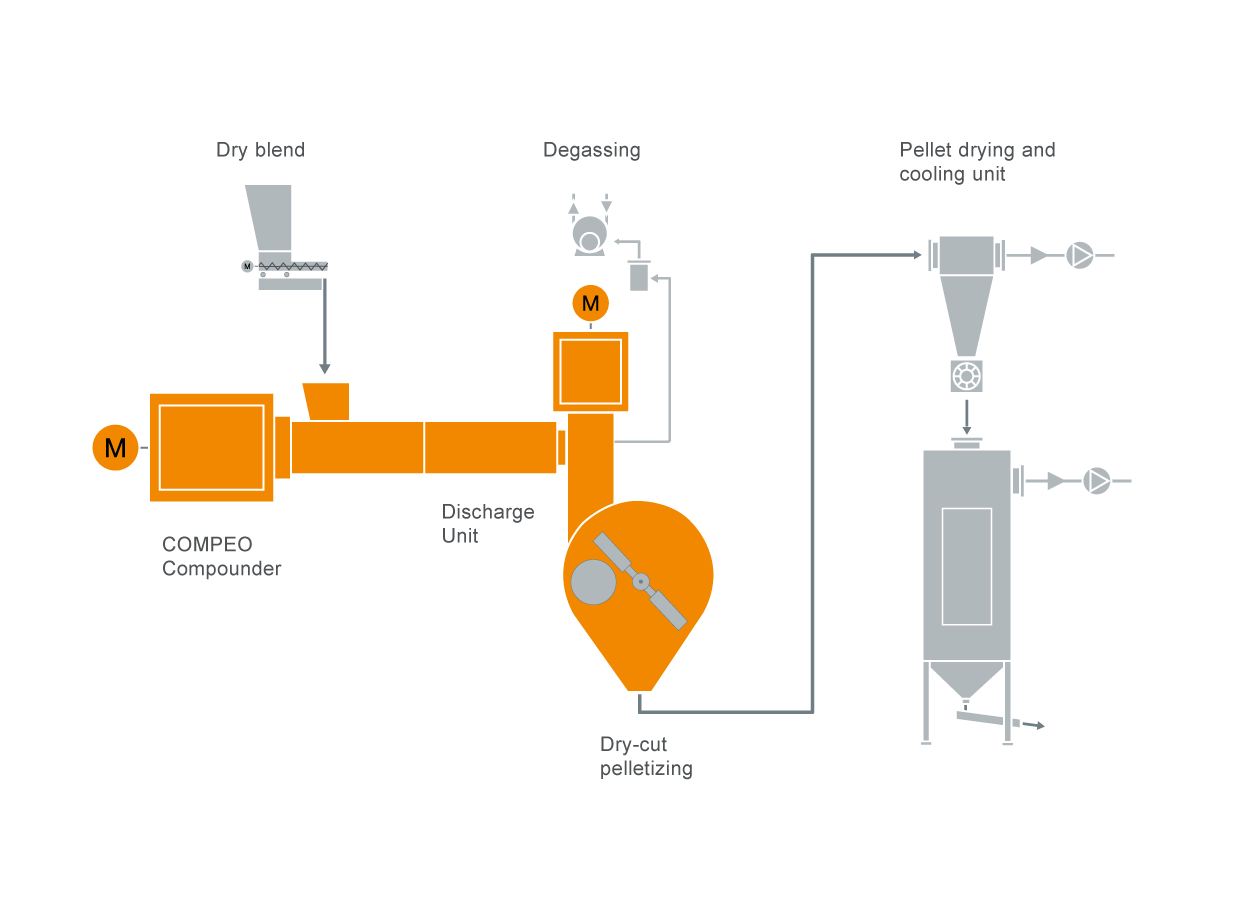

Rigid PVC (PVC-U) is produced in a compounding machinery by hot/cold mixing in the powder phase. For all subsequent processes requiring pellets, such as injection moulding, this is followed by compounding and pelletizing on a Buss Kneader. This two-stage compounding process likewise applies in case of high fillers content or specific quality demands. For simpler formulations, premixing in the powder phase may be sufficient.

Typical applications

Thanks to its good mechanical, electrical and optical properties, as well as good chemical resistance, rigid PVC is very useful for many applications. It is used in plant and machinery applications for pressure pipes, couplings and fittings, blowers and fans, air ducting, valves, pumps, or in the chemical industry for tanks and liners made of rigid PVC (PVC-U). In the building industry rigid PVC is used e.g. for wastewater pipelines, roof gutters and downpipes, gas pipes, drainage pipes, window frames, facade elements, ventilation shafts and anti-glare screens. In electrical technology, rigid PVC is used for insulating conduits, transparent distribution-box covers, housings and cable conduits. Examples of rigid PVC applications in the packaging industry include diffusion-resistant bottles for oils and other liquids.

Compounding requirements for rigid PVC

Compounding requirements can be summed up as follows. The rigid PVC dryblend powder, which also contains other constituents like stabilizers, additives, fillers, reinforcement materials and flame retardants, must be intensively mixed in the compounding machinery. The dispersive and distributive mixing is critical, and all in compliance with well defined temperature limits.

The Buss Kneader can make the most of its strengths profile at uniform, moderate and if necessary, adjustable shear rates. Compounding and pressurizing are separated and optimized in a two-stage system. Low specific energies with the most intensive mixing processes, volumetric scale-up procedures, and maximum availability are possible thanks to wide operation windows. It is these advantages that underline the technological and market importance gained in rigid PVC compounding technology since the beginning of mass production in the mid twentieth century.

Typical plant layout for compounding rigid PVC

BUSS compounding machinery for rigid PVC offers the following specific benefits

Learn More

Downloads

-

COMPEO