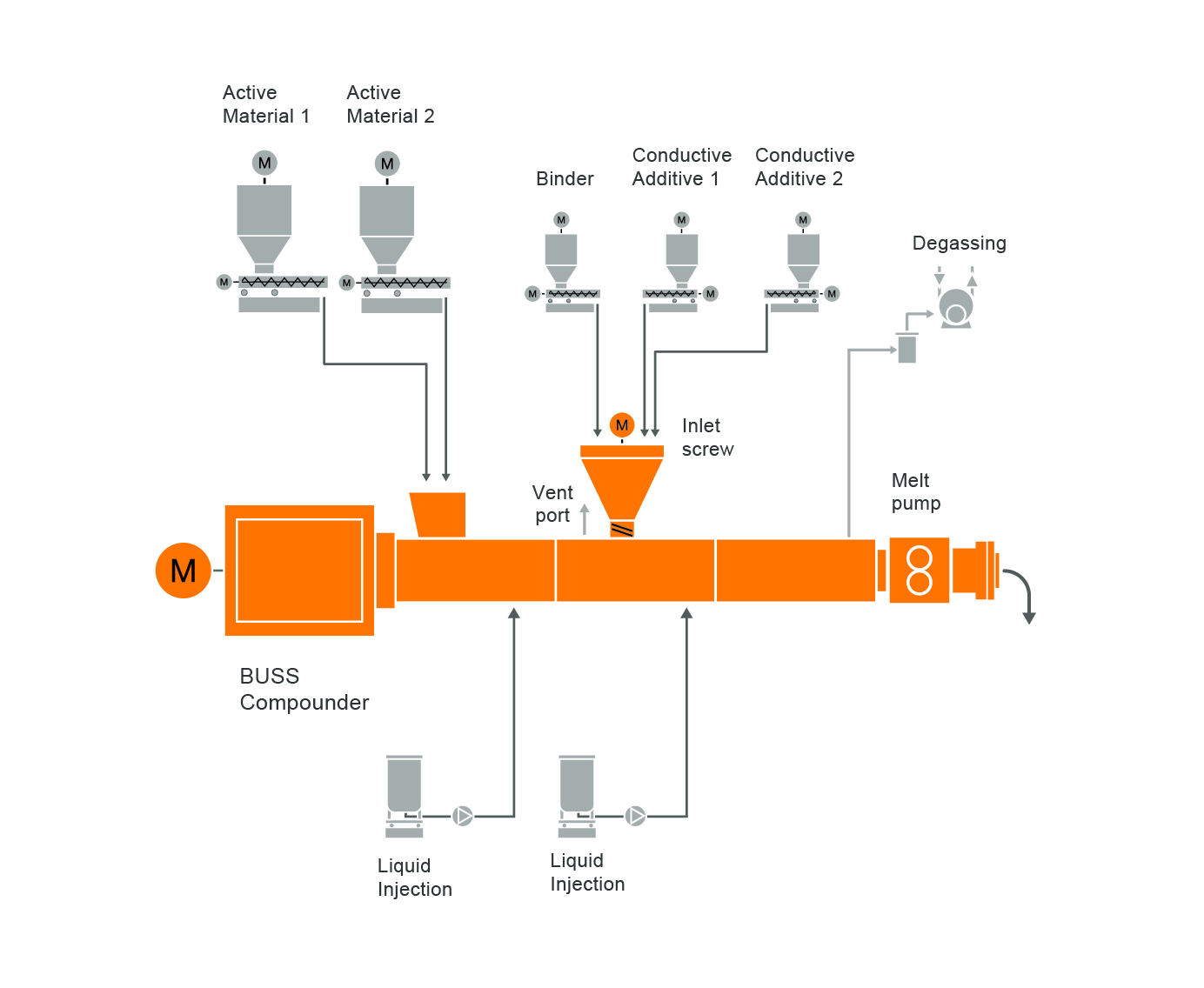

Compounding technology for battery compounds

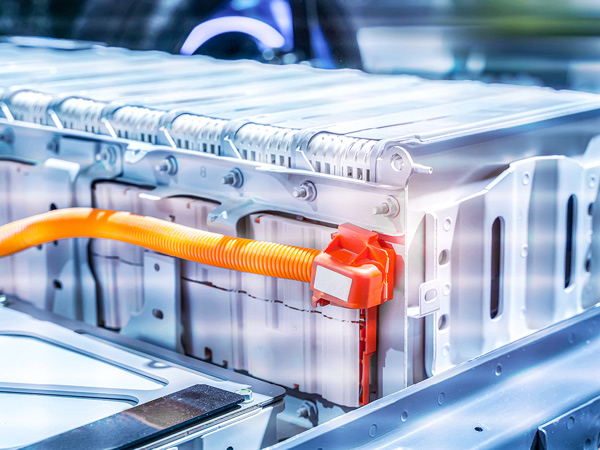

The development and implementation of high-density accumulator and battery systems are important mosaic stones in responding to the global trend and UNO sustainability goals. The sustainable and decentralized generation, storage and use of energy play a key role thereby. In researching target-oriented substance combinations and processes, the handling of electrically conductive materials is of great importance.

Typical requirements include intensive mixing in the solid as well as the viscous phase, without destroying the structure of the functional fillers and thus reducing the conductivity. At the same time, adherence to strict temperature limits is a possible requirement.

The knowledge acquired over decades of handling conductive materials, which may also be on a nano scale (such as graphene or different variants of carbon nanotubes (CNTs) or other materials used in alternative industries, enables BUSS process developers to find, evaluate and successfully apply customized solutions.

Thus, the full potential of continuous systems is exploited: uniform process conditions, tight residence time distribution, continuous process control and assurance as well as the integration of various process steps are among the typically used features.

Processing requirements

This combination of process engineering expertise and the system-specific capabilities of the BUSS Kneader make it possible to implement sophisticated solutions: high proportions of conductive aggregates can be distributed to multiple feeders. The immediate onset of mixing at moderate shear rates and intermediate relaxation phases results in excellent distributive mixing results without damaging the internal structure of the conductive materials and/or polymers. Often, with low levels of conductive components, the same electrical properties or better can be achieved with the same proportions. The result is better processability due to the lower viscosities.

The design freedom of the system also makes it possible to respond specifically to the increasing viscosity in the process zones with targeted configurations. This allows customized control and regulation of the process conditions. Thanks to broadly based process expertise and the BUSS Kneader compounding technology, BUSS as technology leader is the ideal partner in the development and commercialization of sustainable system solutions.

Typical plant layout for processing of battery compounds