HFFR Cable Compounding

HFFR (Halogen Free, Flame Retardant) polyolefin compounds for cable insulation mass can be produced best with HFFR cable compounding systems.

Polyolefins have outstanding insulation properties, but are so easily combustible that they have to be made flame-retardant accordingly. In the early 1980s the first alternatives to PVC compounds, used almost exclusively until then, were developed. This development was also pushed forward by the growing public concern about the release of hazardous substances in general and about fire outbreaks in particular.

Recently, tighter European Construction Products Regulations (CPR) came into force. Their purpose is to protect people, property and the environment by further reducing fire risk, delaying fire outbreak, and minimizing smoke formation. HFFR cable compounds produced with the HFFR cable compounding systems by BUSS AG meet these European safety standards.

For cable mass, these CPR HFFR regulations are best met in many cases by light-metal hydroxide based flame retardants (ATH, MDH). Over the years, further concepts and materials such as milled mineral substances and nanofillers have been developed. The expensive original speciality is meanwhile mass-produced at almost the same price level as PVC compounds.

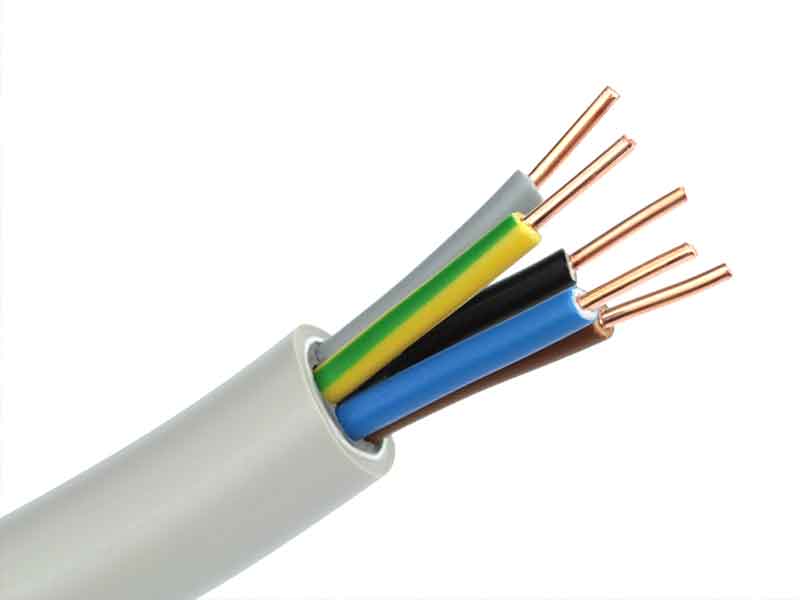

Typical applications of HFFR cable compounds

In Europe the legal regulations mentioned above demand the use of HFFR compounds for public facilities and installations including buildings, tunnels and transportation. In future these regulations are also expected to apply in India, China and the Middle East. In plant and engineering construction, the use of HFFR compounds for complex and safety-relevant installations such as power stations, industrial, chemical and pharmaceutical plants, data centres, etc. has prevailed in order to minimize risks and consequential damages. In order to meet the demanding requirements for flame retardant properties, it is generally necessary to add 50-70 % of the appropriate fillers. For some applications, as much as 80% is needed. This has challenging consequences with regard to the other physical properties, as well as the compounding process, cable manufacturing, and end use. Formulations are therefore preferred with PE-copolymers, which enable higher filler absorption. Coupling and/or cross-linking systems are integrated in order to attain the required mechanical and application-relevant properties. The HFFR cable compounding technology of the BUSS compoundin systems overcomes these challenges from the production process side.

Compounding requirements

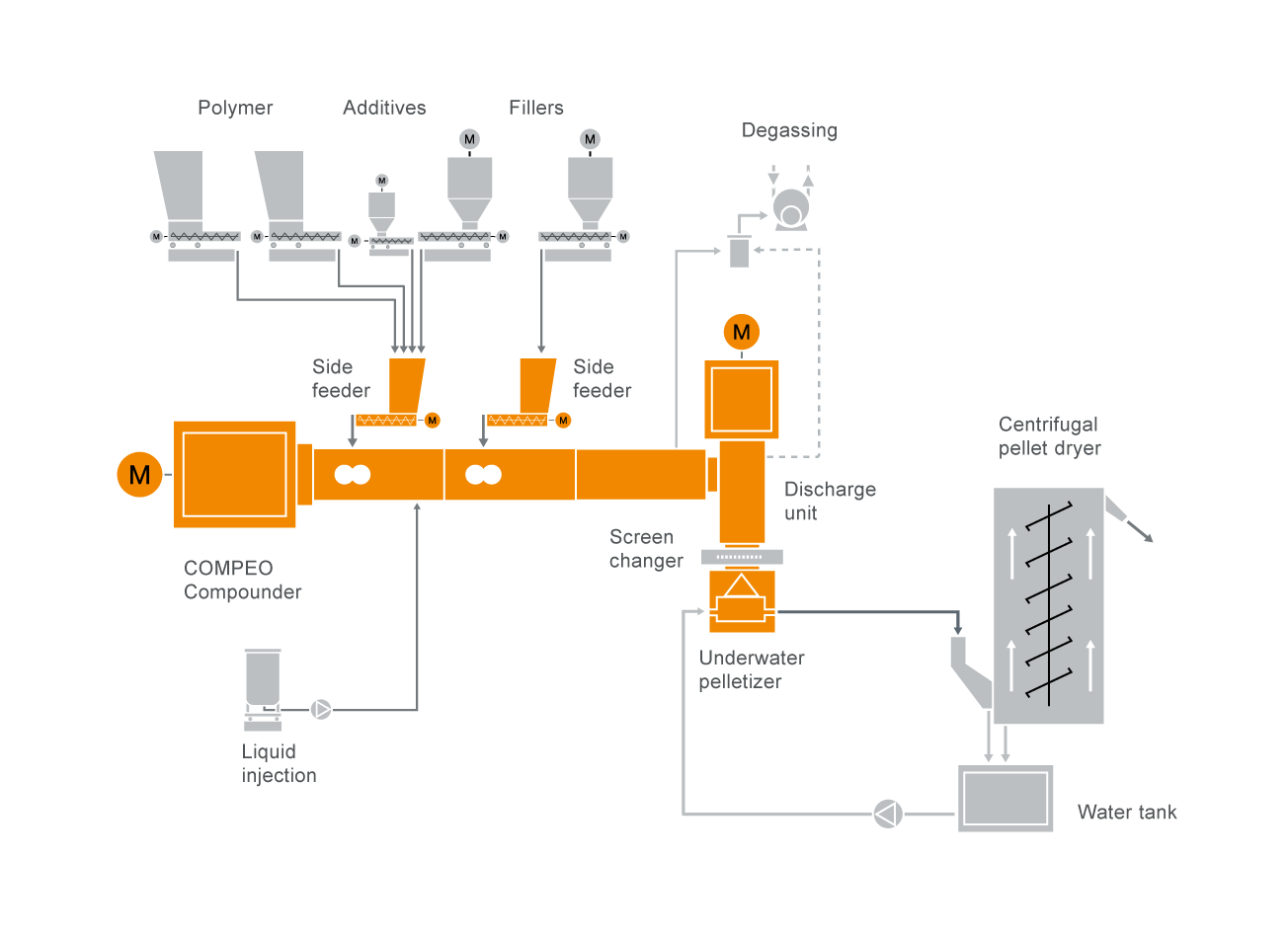

Compounding requirements include, above all, dispersive and distributive mixing at low melt temperatures (< 190°C for ATH) in order to process the additives and high content of flame retardants according to industry requirements. Also indispensable are multiple dosing streams of dry formulation components, and injection of the reactant liquids in defined positions.

The Buss Kneader’s specific capabilities are outstandingly suitable for such applications as mentioned above. Thanks to its operating principle, the enormous number of mixing cycles, at moderate and uniform shear rates, enables the highest possible mixing efficiency and resultant product quality at maximum throughput. As a side effect of the moderate shear rates, wear and tear is significantly lower then with other kinds of screw extruders. The process chamber is modularly designed by in-house experts according to specific applications. It can therefore be adapted at any time to changing requirements. The positioning of the liquid injectors, at almost any desired points along the process section, serves as a unique process design parameter for systematically influencing the reactive processes. The entire compounding line can be continuously monitored by means of respective temperature measurement at any point along the process chamber. This greatly facilitates online quality assurance and control.

The Buss Kneader’s two-stage system deliberately separates the compounding and pressure build-up stages so that each stage can be independently optimized. The hinged housing of the Buss Kneader and the retractable casing of the discharge extruder ensure fast and easy access for high system availability.

Together with broadly based Buss process expertise, the modular design and therefore adaptable arrangement of the entire compounding line make the Buss Kneader first choice for cable insulation mass made with HFFR cable compounding, with maximum investment security.

Typical plant layout for HFFR Cable Compounding Systems

BUSS HFFR cable compounding systems offer the following specific benefits

Learn More

Downloads

-

COMPEO