Polyamide Compounding Systems

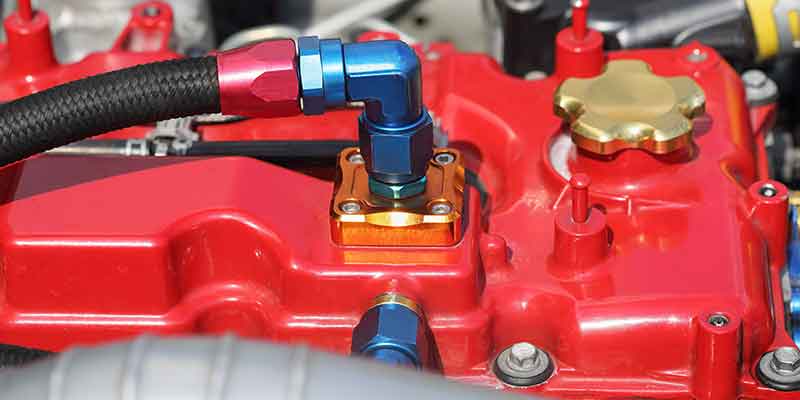

Polyamide (PA) or Nylon based compounds belong to the technical plastics sector, often known as Engineering Plastics due to their main strengths and respective applications: technical components for stringent mechanical and thermal requirements, with good resistance to aggressive chemicals and demanding environments.

Polyamides were developed by DuPont and launched in 1934. First used for textiles and fabrics of all kinds, their applications were soon extended to include injection moulding and extrusion. Further development then focused on application temperatures and reduction of water absorption. Semi-aromatic high-performance polyamides, also known as polyphthalamides (PPA), are heat distortion resistant up to 280°C. The other outstanding properties of PA include high rigidity, good electrical characteristics, and highly attainable flame retardancy.

Compounding requirements for polyamide compounds

These specific characteristics are programmed at the compounding stage, often using a combination of reinforcing agents, fillers, flame retardants and other additives. Compounding polyamides is therefore very demanding and requires customized solutions accordingly. These solutions are given with the BUSS polyamide compounding systems. Specific energy inputs have to be as gentle as possible, large amounts of fillers and flame retardants have to be perfectly distributed, and reinforcement fibres must be added so as to optimize mechanical properties while at the same time maintaining high dwell times in the respective process zones.

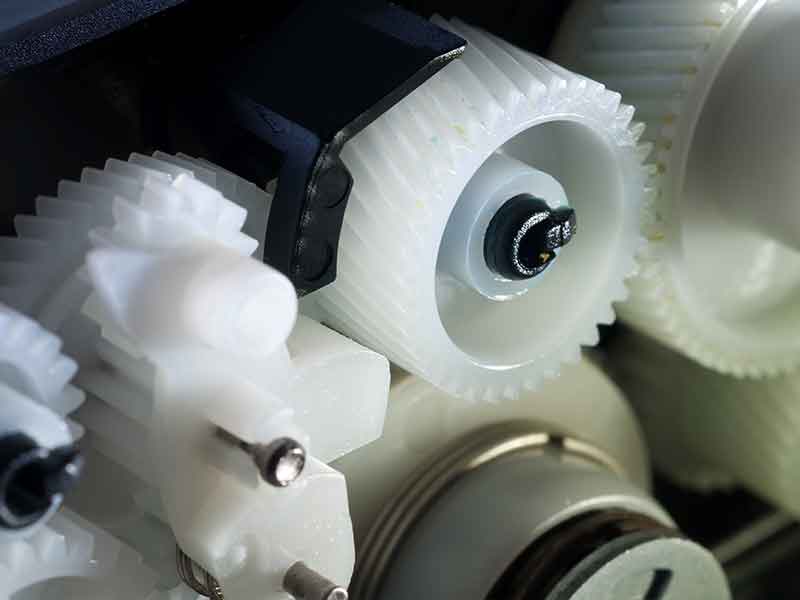

Although contradictory in part, all these requirements are well mastered by sophisticated process technology. The BUSS Kneader has proven itself again and again for compounding such highly demanding materials. This is mainly because of its moderate and uniform shear rates, which can be customized, if necessary, to ensure precise temperature control. As a result, just enough energy is dissipated in the melting zone to avoid overstressing the polymer fractions. Thanks to high folding rates, the fillers and flame retardants are optimally distributed over the shortest possible processing length. The reinforcement fibres added, if necessary, downstream are separated and sheathed in order to preserve maximum fibre length. Even with the narrowest process window such as for PPA based materials, with only 30°C temperature margin between melting and incipient breakdown. it is possible to achieve the best characteristics profile also at the highest viscosities.

The BUSS Kneader’s two-stage system clearly separates the compounding and pressure build-up stages so that each stage can be independently optimized. The hinged housing of the BUSS Kneader ensures fast and easy access for high system availability. Together with broadly based BUSS process expertise, the modular design and therefore adaptable arrangement of the entire compounding line make the BUSS Kneader within the whole polyamide compounding system first choice for complex polyamide production at high quality levels, with maximum investment security.

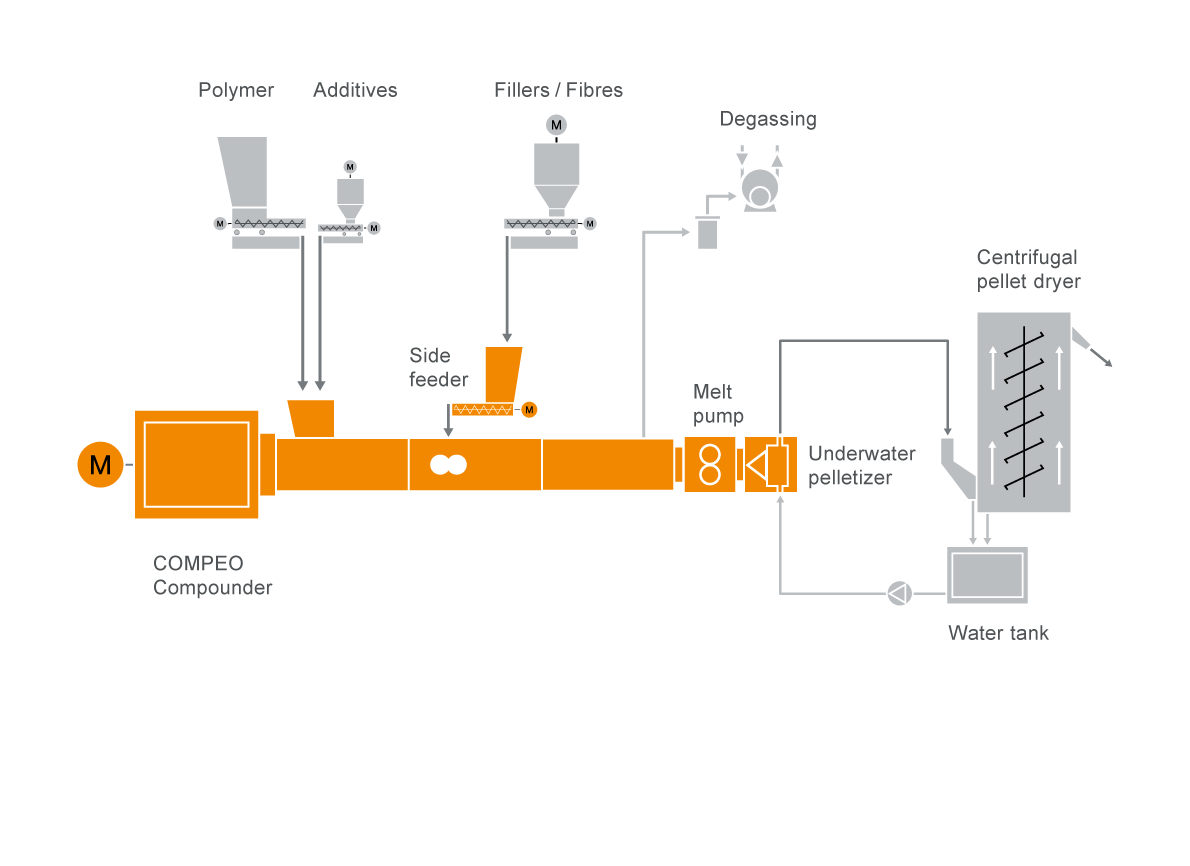

Typical plant layout for polyamide compounding systems

BUSS polyamide compounding systems offer the following specific benefits

Learn More

Downloads

-

COMPEO

-

Laboratory Kneader MX 30